Food & Beverage Liquid Flow Switch

Applications:

Milk Flow Monitoring

Beverage Monitoring

Food Process Monitoring

3A Sanitary Flow Switch

Sanitary Flow/No Flow Switch

Application Background:

The food, beverage, and pharmaceutical industries are challenged in their production and storage processes to maintain sanitary conditions in their pipes, lines, tanks, and vats. The milk industry recognized this early on and established the 3A Sanitary Guideline and specification rating system.

Traditional flow switches needed to monitor and confirm liquid product flow in such process pipes do not satisfy the 3A Standards with their normal construction designs. Even if constructed of stainless steel, traditional switch designs do not address the surface finish and crevice radius requirements of the Standard.

Application Solution:

There are many liquid flow monitoring technologies including: site glasses, paddle/flapper types, turbine, capacitance, vibrating forks, ultrasonic, and conductance probes. All have proven to work with varying degrees of success. Some rely on operator’s time and attention, while some have mechanical parts and are prone to wear, hang-up, and failure. Still other electronic type probes require conductive fluids or fluids of specific capacitance. Many of these technologies have been redesigned to meet the 3A Sanitary Design Standards.

One of the better solutions for liquid flow detection at a specific point in a sanitary process line is the Thermal Differential Switch. The TD switch has two thermal sensing devices (RTD’s) encased in stainless steel tips. One sensor detects the temperature of the liquid while the second has a small current applied to create a thermal differential above the fluid temperature. The differential temperature between a fluid flowing and not flowing is different. Therefore the detection of flow at the sensor probe is a simple, reliable technique for a point flow monitor.

With a single process connection into a pipe line through a 3A Sanitary flange fitting, a TD probe can be strategically located to monitor for flow of the process fluid. When the probe detects the fluid, the TD switch activates a relay output to confirm that flow is occurring.

Recommended Products:

Sanitary Cleaning System Monitor - Fire Suppression System

Heat Transfer Fluid Monitoring - Gas Purge Confirmation

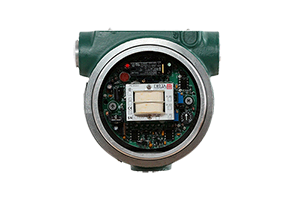

- CSA, Ex, CE, CENELEC, 3A, NEMA4x

- Choose 110VAC, 220VAC or 24VDC Electronics

- Rugged and Reliable for any application

- Available in SS, Hastelloy, Titanium & More

- Wide selection of Standard or Custom sensor designs

- Quick Response Time

w/ Unit Diagnostics

Safety Relief Valve Monitor - Soot Blower Feed Water Monitor

Rotating Equipment Lubrication - Vapor Recovery Monitor

Gas Booster Monitor - Food & Beverage Liquid Flow Monitor

- User Selectable Power – 110/220VAC/24VDC

- Optional Remote Electronics for easy setup

- Nearly any Process Connection - Custom or Common

- Wide operating temperature range up to 850F

- 2nd Channel for Detection of Unit Diagnostics

- Two year workmanship warranty