Dual Channel Liquid Flow With Dry Line Indicator

Flow Applications |

Dual Channel Liquid Flow

+ Dry Line Indication

Applications:

Pump Protection

Dry Line Indicator

Dry Line Alarm

Liquid Flow Switch

Application Background:

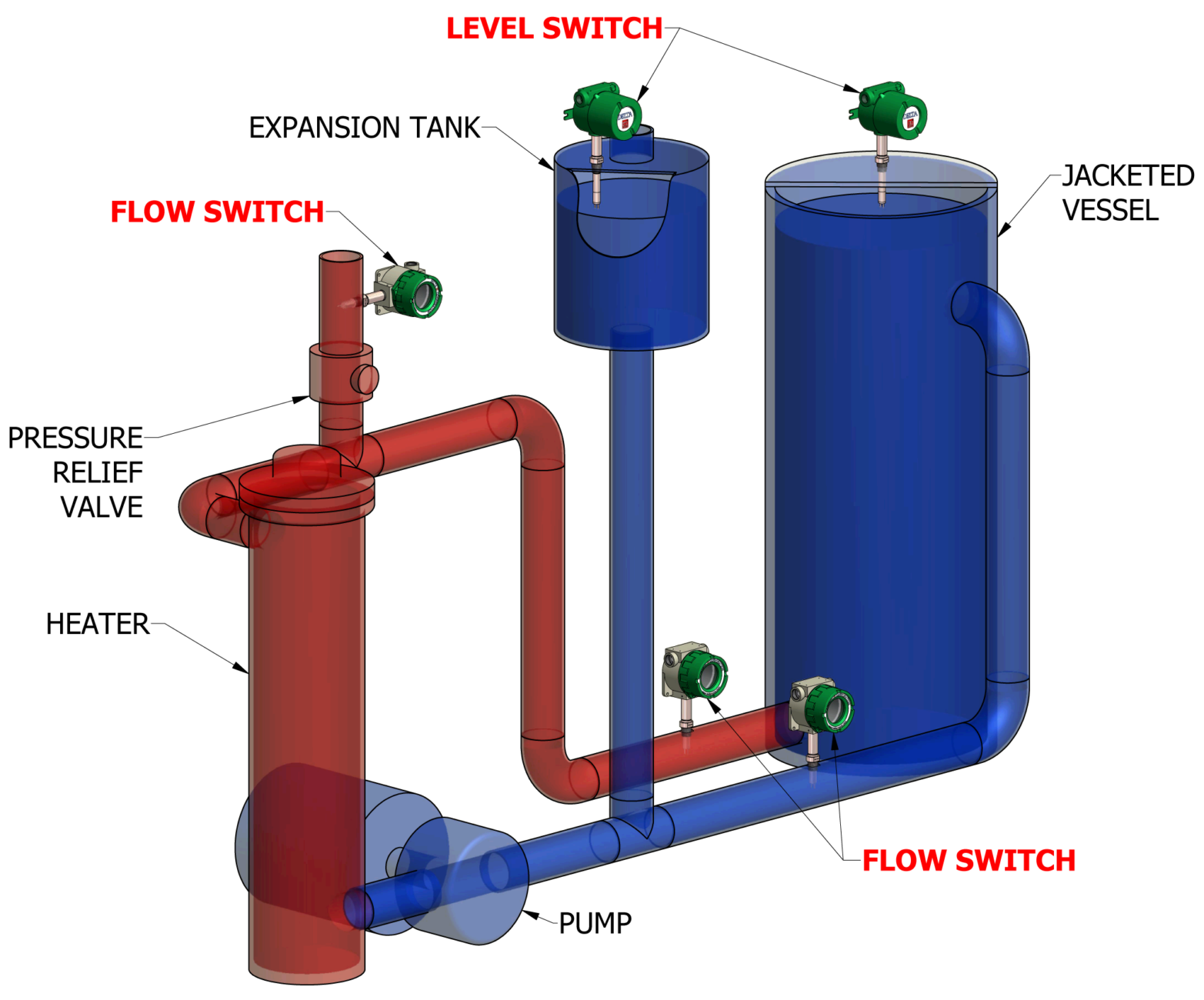

It is often desirable to monitor the flow of a liquid being pumped in a process. In addition to metering the fluid, a simple flow switch can provide confirmation of flow or flow at a minimum acceptable volume for proper operation. For added pump protection, a dry line detector, indicator, or alarm is an ideal feature, especially for larger, expensive pumps in critical applications.

Application Solutions:

A flow switch with dual channels has the capability of setting two discrete flow set points. Normally the first channel would be set for “no flow” or “dry line” condition and the second channel for the desired flow set point or some minimum flow to prevent the pump from cavitations.

With a single process connection into the inlet flow pipe (MNPT or flange), a Dual Channel Versa-Switch from Delta M Corporation can provide true pump protection.